3D bioprinting of tissues using natural biomolecules

– Monmita Bhar (with input from authors)

Organs damaged by disease or injury can be replaced with healthy organs from donors using transplantation. However, transplantation has limitations such as the risk of infection, shortage of donated organs, and the possibility of rejection by the recipient’s immune system. This has motivated tissue engineers to develop safer lab-based alternatives.

The emergence of 3D printing technology in recent years enables the fabrication of complex parts layer-upon-layer. Tissue engineering focuses on tissue and organ regeneration by creating scaffolds using biomaterials called bioinks. Bioinks constitute cultured cells and biocompatible materials like a hydrogel, and are specific to the tissue being transplanted.The scaffolds are 3D printed, maintaining structural and functional compatibility with human tissues, ranging from soft tissues to bone, which arethe most commonly transplanted tissues.

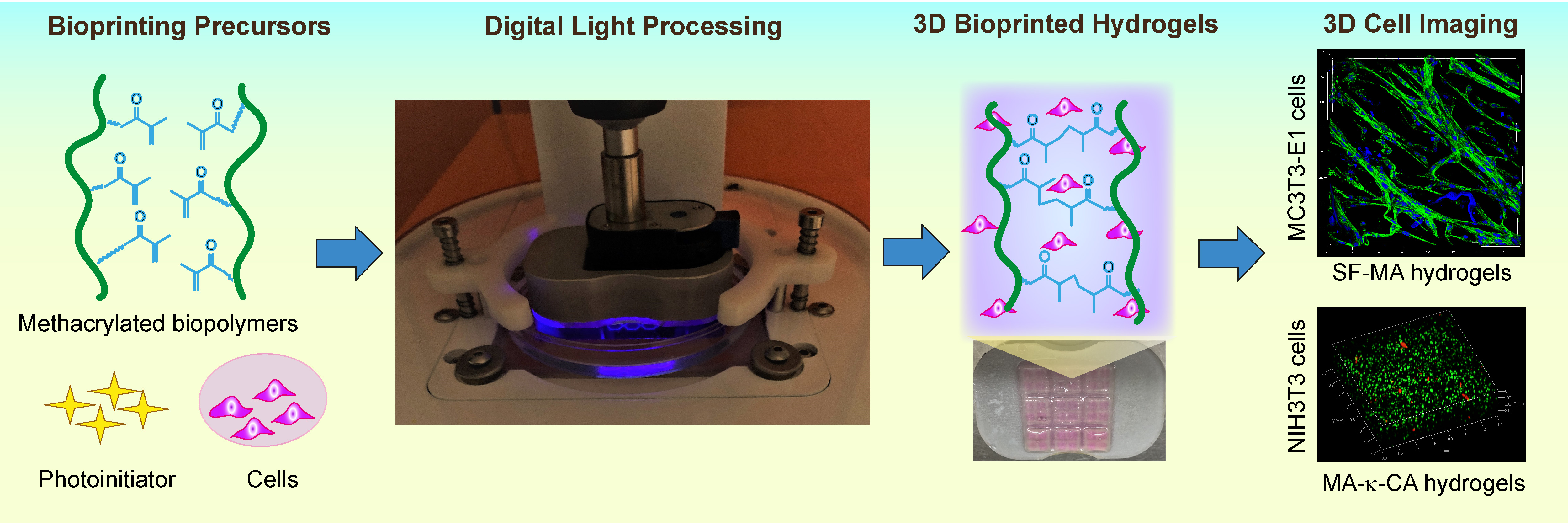

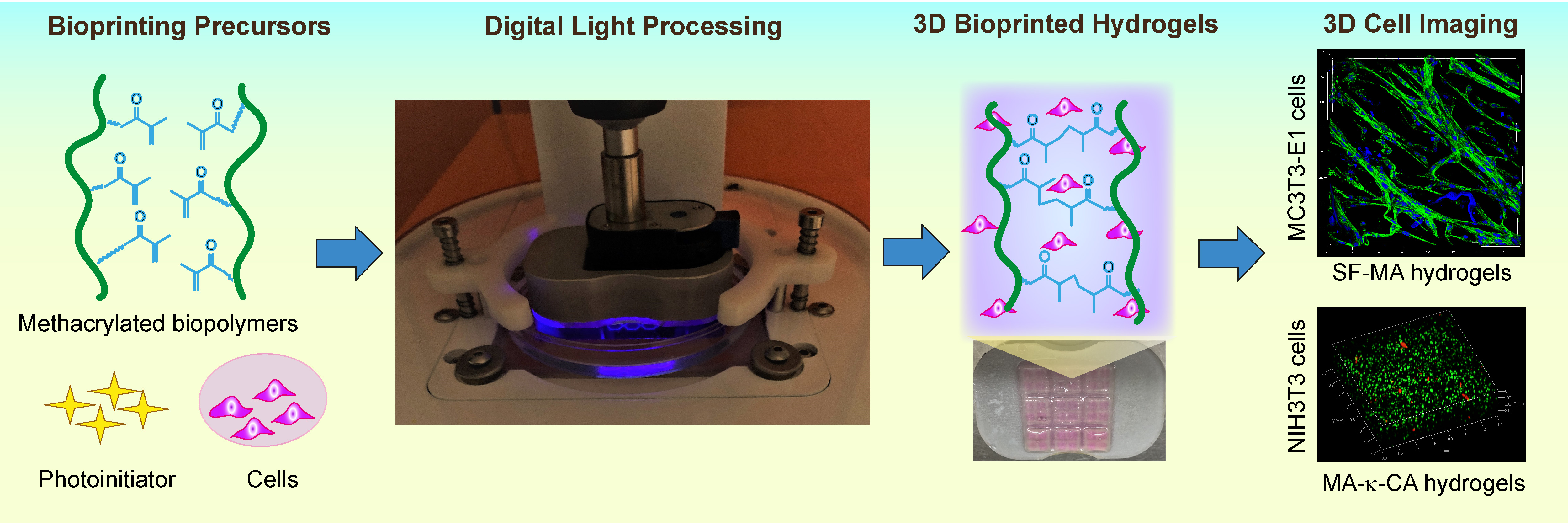

Several macromolecules are being developed to prepare bioinks to optimally recapitulate native human tissues. In the past, digital light processing (DLP)-based3D bioprinting has been attempted where UV light selectively crosslinks the macromolecules to generate the scaffold. Although this technique can print complex structures at a high resolution, it uses UV light, which is known to cause DNA damage in the cells during printing.KaushikChatterjee, Associate Professor at the Department of Materials Engineering, and his team addressed this issue by using visible blue light radiation (405 nm) instead of UV. This new technique shows promise in building tissue scaffolds that mimic the tissue microenvironment structurally and functionally. In two recent studies, they have applied this technology to prepare tissue scaffolds from proteins and polysaccharides.

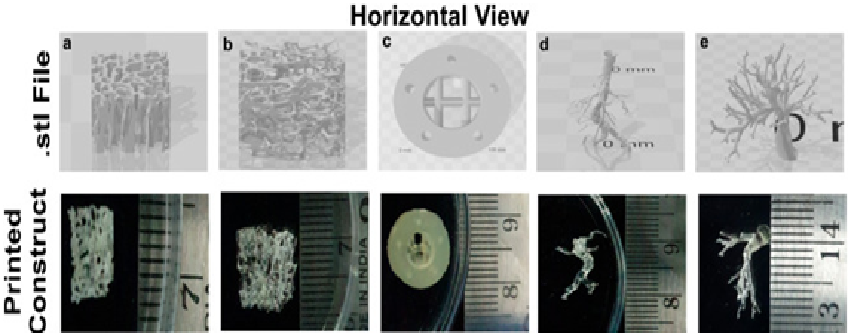

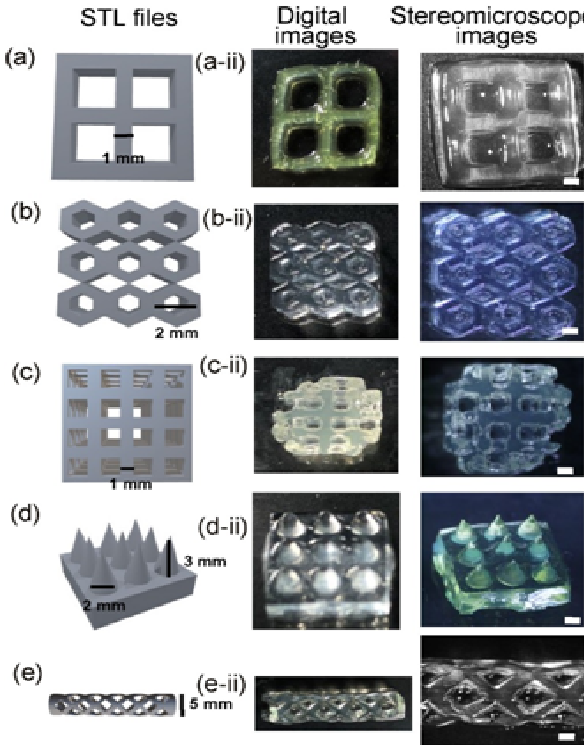

Silk fibroin (SF), a fibrous protein extracted from Bombyx mori (the silkworm), resembles Collagen I, a major component of bone. The team successfully prepared bioprinted SF scaffolds for bone tissue regeneration. In another study, the team carried out experiments with κ-carrageenan, a naturally occurring polysaccharide resembling essential components of connective tissues, and demonstrated that it could be used as a component in bioinks for soft tissues. These studies broaden the horizonin the search for novel bioinks towards ultimately enabling tissue generation for clinical use.

REFERENCE:

Rajput M, Mondal P, Yadav P, Chatterjee K, Light-based 3D bioprinting of bone tissue scaffolds with tunable mechanical properties and architecture from photocurable silk fibroin, International Journal of Biological Macromolecules (2022), Volume 202, Pages 644-656

Kumari S, Mondal P, Chatterjee K, Digital light processing-based 3D bioprinting of κ-carrageenan hydrogels for engineering cell-loaded tissue scaffolds,Carbohydrate Polymers(2022), Volume 290, Page 119508

WEBSITE LINK:

https://sites.google.com/site/iiscbiomaterials

Photograph of the authors:

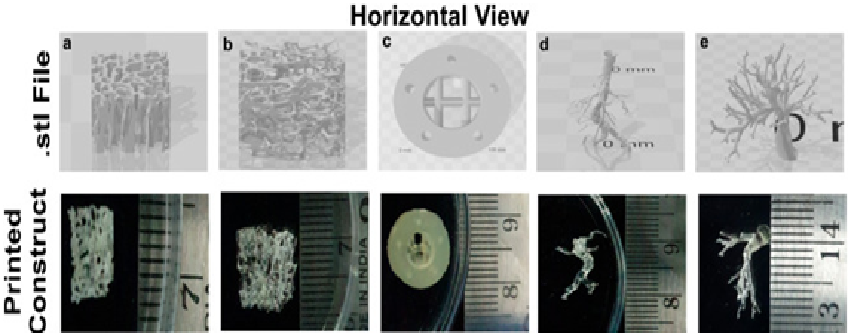

Figure 1.STL file and corresponding photographs of the 3D printed hydrogels demonstrating the printability of 15% SF-MA by DLP 3D bioprinter. (a, b) Trabecular bone, (c) Haversian bone, (d, e) vascular network.

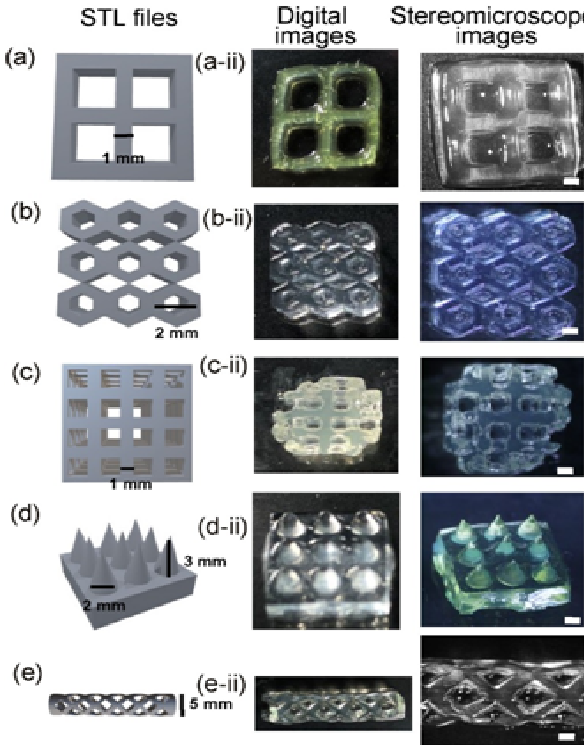

Figure 2.STL files and corresponding digital images and stereomicroscope images of DLP printed 3% (w/v) MA-κ-CA porous scaffolds. (a) grid, (b) honeycomb, (c) cube with lumen, (d) fine needles, and (e) BioStent Scale bars: 1 mm.