Designing next generation batteries by engineering mixed polyanionic cathode materials

‘Building better batteries’ remains an ongoing process to cater diverse energy demands starting from small-scale consumer electronics to large-scale automobiles and grid-storage. While Li-ion batteries have carried this burden over the last three decades, the ever-growing and highly diverse applications (based on size, energy-density and stationary vs. mobile usages) have led to an era of ‘beyond lithium-ion batteries’. In this post-lithium-battery genre, sodium-ion batteries (NIBs) have emerged as a pragmatic option particularly for large-scale applications. They attract attention due to the abundance and uniform geographic distribution of sodium-based minerals, materials/ process economy and well-known (de)intercalation mechanism in particular for stationary applications independent of size/ weight restriction.

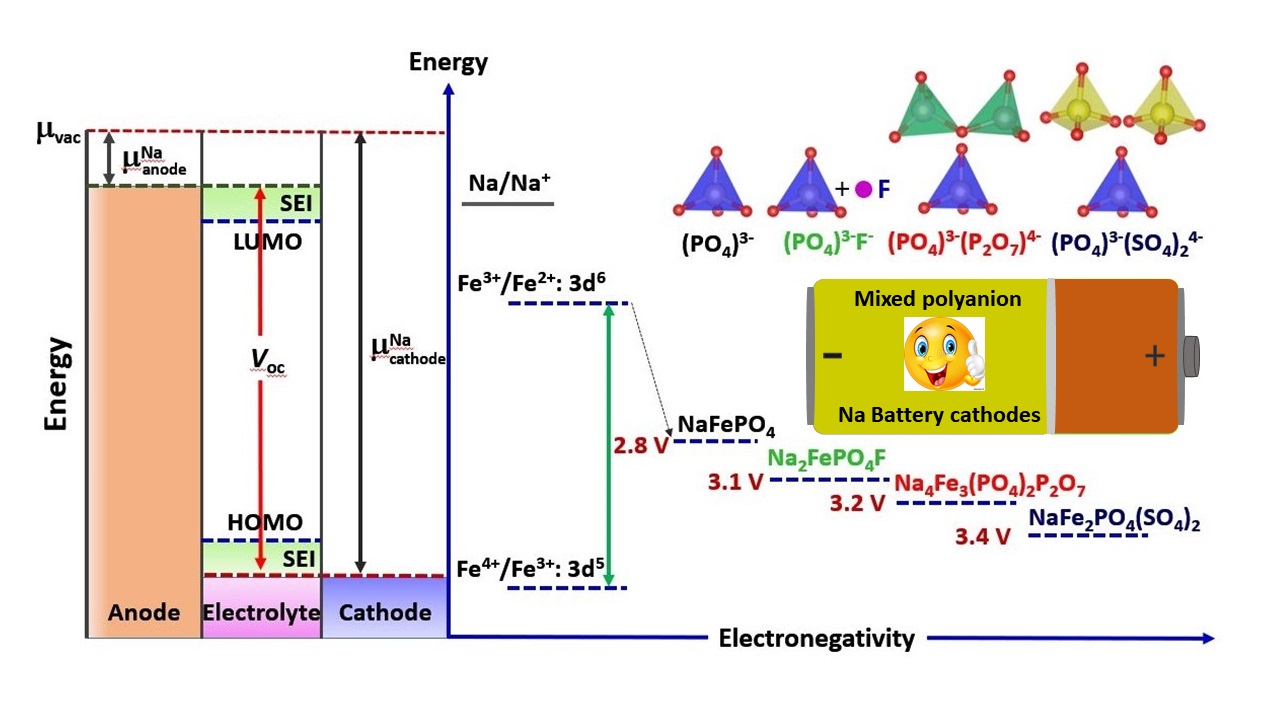

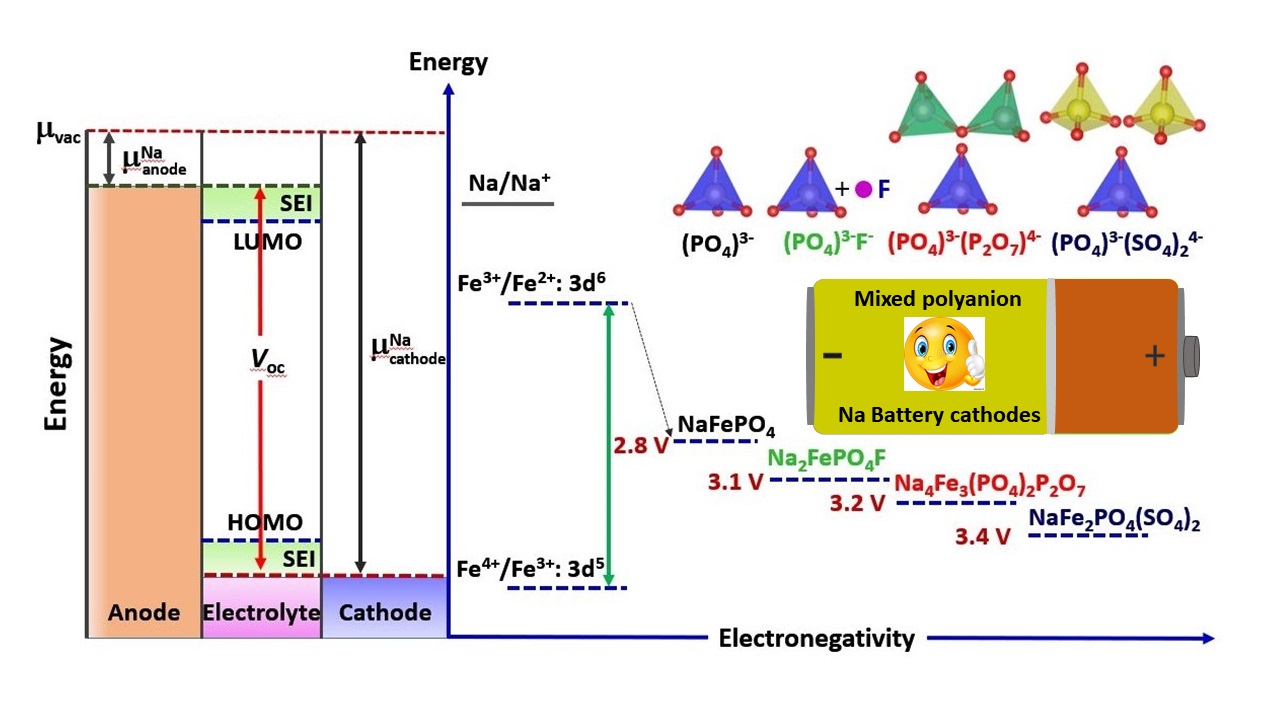

Parallel to the Li-ion batteries, cathode (+ve electrode) plays a key role in overall performance leading to the exploration of various layered and three-dimensional framework insertion materials. While layered oxides deliver high capacity, polyanionic hosts offer structural stability, operational safety and tunable redox potentials. It can be further exploited in ‘mixed polyanion’ cathode materials combining more than one kind of polyanion units. Our current article dwells into the world of mixed polyanionic cathode materials to realize next generation sodium-ion batteries with high energy density.

Parallel to the Li-ion batteries, cathode (+ve electrode) plays a key role in overall performance leading to the exploration of various layered and three-dimensional framework insertion materials. While layered oxides deliver high capacity, polyanionic hosts offer structural stability, operational safety and tunable redox potentials. It can be further exploited in ‘mixed polyanion’ cathode materials combining more than one kind of polyanion units. Our current article dwells into the world of mixed polyanionic cathode materials to realize next generation sodium-ion batteries with high energy density.

Group webpage: http://www.mrc.iisc.ac.in/prabeer-barpanda/

Relevant references:

(i) P. Barpanda et al, Adv. Energy Mater, 8(27), 1703055, 2018.

(ii) R. Gond et al, ChemElectroChem, 5(1), 153-158, 2018.

(iii) L. Sharma et al, ACS Appl. Mater. Interfaces, 9(4), 34961-34969, 2017.

Parallel to the Li-ion batteries, cathode (+ve electrode) plays a key role in overall performance leading to the exploration of various layered and three-dimensional framework insertion materials. While layered oxides deliver high capacity, polyanionic hosts offer structural stability, operational safety and tunable redox potentials. It can be further exploited in ‘mixed polyanion’ cathode materials combining more than one kind of polyanion units. Our current article dwells into the world of mixed polyanionic cathode materials to realize next generation sodium-ion batteries with high energy density.

Parallel to the Li-ion batteries, cathode (+ve electrode) plays a key role in overall performance leading to the exploration of various layered and three-dimensional framework insertion materials. While layered oxides deliver high capacity, polyanionic hosts offer structural stability, operational safety and tunable redox potentials. It can be further exploited in ‘mixed polyanion’ cathode materials combining more than one kind of polyanion units. Our current article dwells into the world of mixed polyanionic cathode materials to realize next generation sodium-ion batteries with high energy density.