Graphene nanoresonator as strain sensor

Sensors that produce a measurable response to the applied mechanical deformation are useful in many applications including personal and structural health monitoring. One of the ways to make these strain sensors is by fabricating small string-like vibrating structures called nanoresonators. These tiny (sub-10um) structures, made of materials such as graphene, vibrate at ultrahigh frequencies (10-100MHz) and are exquisitely sensitive to changes in the strain. However, introducing the strain stimuli into these sensors implies that the devices have to fabricated on flexible substrates such as PDMS and PET. The fabrication process on these substrates are complex and device yields are small.

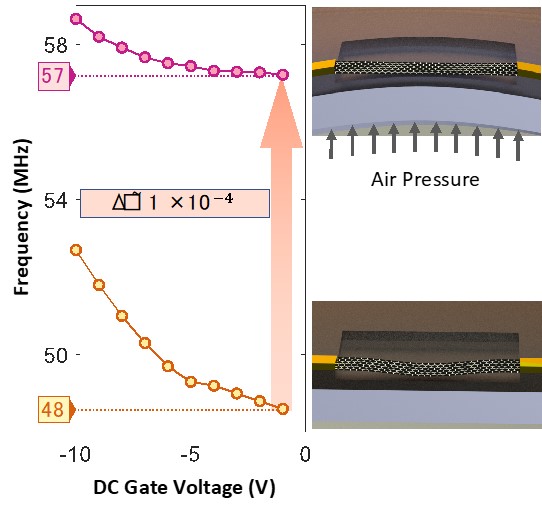

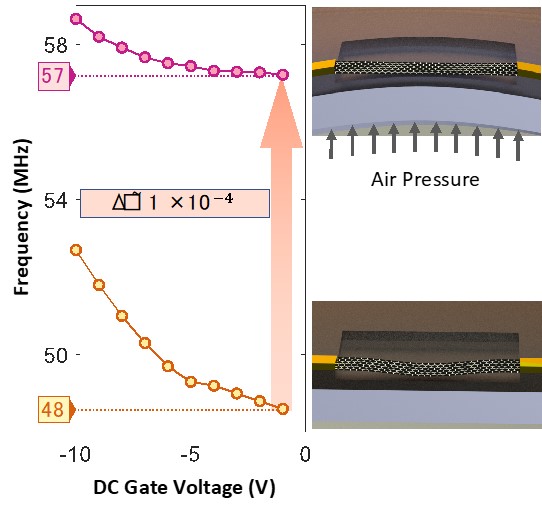

Swapnil More, PhD student in Akshay Naik’s lab at the Centre for Nano Science and Engineering (CeNSE), developed a simple method to fabricate these devices on a thin diaphragm on silicon substrates. He then utilised air pressure to deform the substrate on which NEMS are fabricated. This controlled deformation of the substrate induces strain in the nano resonator and changes the resonant frequency. The magnitude of this strain change can be deduced using the frequency tuning of the nano resonator. Strain changes as low as 10-9 can be measured using these devices. This method can be used with a wide variety of nanomechanical systems. Besides their utility as sensors, strain-tuneable nano resonators form interesting tools to study some of the most intriguing dynamical phenomena such as synchronization, mode coupling and internal resonance.

References :

https://iopscience.iop.org/article/10.1088/1361-6439/abe20b

http://www.cense.iisc.ac.in/anaik/