Novel diaphragm and micro-stylus based FBG tactile sensor

-Aniket Majumdar

To grasp an object correctly, robotic hands use tactile sensors that can inspect the surface of the object and provide information about its texture, shape, composition, and temperature. Tactile sensors are also used to read Braille scripts, locate tumors in open surgeries, monitor pulse rate and heartbeat in wearable devices, and carefully inspect surfaces in agriculture, food processing and manufacturing industries. Over the years, various tactile sensors have been developed, but these are generally expensive, difficult to manufacture and not designed efficiently. To address this, researchers from the Indian Institute of Science (IISc) have developed a novel diaphragm and micro-stylus-based Fibre Bragg Grating (FBG) tactile sensor.

An FBG is an optical device that is fabricated along the axis of an optical fiber cable. When a broadband signal propagates through the FBG, only a specific wavelength gets reflected while the rest is transmitted through the fibre. If the cable and subsequently the FBG are subjected to a force or a change in temperature by some random object, the reflected wavelength shifts by some amount. Monitoring this shift gives some information about the object.

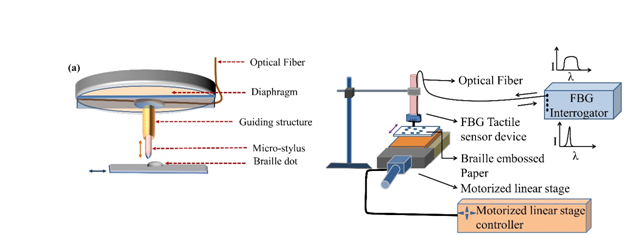

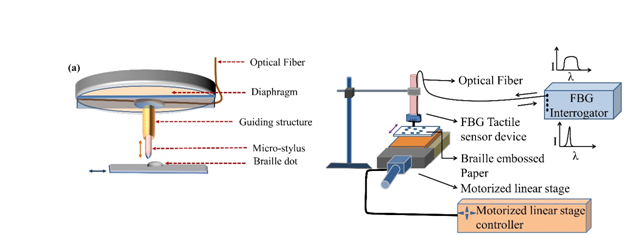

In the newly-developed tactile sensor, the IISc team used a combination of a diaphragm and a freely moving micro-stylus (MS) ‒ which looks like the tip of a ballpoint pen ‒ as the “random object”, which “disturbs” the FBG depending on the surface texture. Their sensor exhibits nearly 80 times higher sensitivity compared to existing devices, the researchers say.

Figure (a): Diaphragm and micro-stylus based FBG tactile sensor. The image on the right is a schematic of the experimental setup.

The team used their sensor to “read” Standard English Grade-1 Braille cells, a functionality that might help people who have lost their eyesight during the course of their life avoid having to learn Braille at such a late stage. While scanning the surface of the Braille-embossed paper, the tip of the MS touches the curved surface of the hemispherical Braille dot. This pushes the MS upward, which deflects the diaphragm, which in turn compresses the attached FBG sensor. The data recorded by the sensor is then converted to English alphabets using an algorithm. These alphabets could potentially be communicated to the user as an audio signal.

Compared to existing tactile sensors, FBG sensors have many advantages: small size, high sensitivity, fast response, ease of remote deployment, reduced connectivity requirements, immunity to electromagnetic interference, and multiplexing capability. This FBG tactile sensor is a promising candidate for various applications related to surface measurement.

REFERENCE:

Asha Prasad, Suneetha Sebastian and Sundarrajan Asokan, Diaphragm-Micro-stylus Based Fiber Bragg Grating Tactile sensor, IEEE Sensors Journal, February 2020. “https://ieeexplore.ieee.org/document/9006899“

LAB WEBSITE: http://iap.iisc.ac.in/~sasokan/