4D printing for artificial blood vessels

– Yukta Subramanian

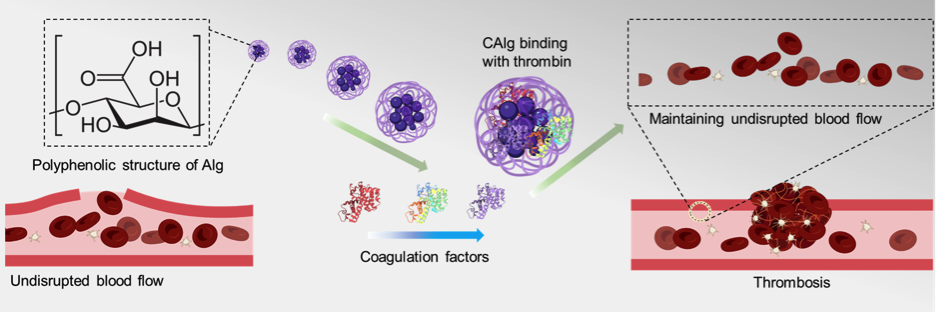

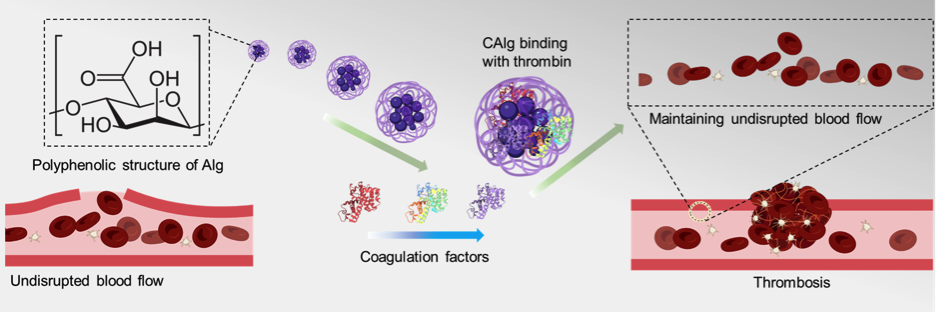

Anti-thrombogenic properties of the nanoengineered hydrogel-based vascular graft (Image: Amit Nain)

3D printing is like building a sand castle – adding material layer by layer until your digital blueprint turns into a physical object. While this allows precise design, the static nature of the objects created makes it a poor choice for applications such as scaffolds that can support the growth, organisation and functioning of cells and tissues. 4D printing resolves this by adding a fourth dimension to the design process: time. In 4D printing, special materials that can change their structure when exposed to stimuli like heat, light, or chemicals are used.

Researchers at the Departments of Materials Engineering and Bioengineering led by Kaushik Chatterjee and Amit Nain, along with their collaborators applied this technique to create artificial blood vessels that closely resemble real ones. These could be used as grafts (replacements) for blocked, injured or damaged blood vessels.

The group has developed a specially formulated nanoengineered hydrogel ink that is first printed into sheets. These 3D-printed flat sheets self-fold into tubular structures when immersed in a calcium chloride solution. The team coated the surface of the vessels with gelatin, to allow cells to stick to it. The gel formulation was chemically modified prior to 3D printing to give the printed structures anti-oxidative and anti-inflammatory properties, along with very low clotting potential and significant bio-compatibility.

In addition, the team created a computational model that predicts shape deformations for constructs prepared using the nanoengineered hydrogel formulations. They used a predictive modelling-based approach to evaluate how different designs can lead to tubes of different shapes, such as bifurcated vessels seen inside the human body.

Current grafts require additional surgeries, carry risks of rejection and disease transmission, and are prone to clotting and other complications. These artificial blood vessels are a step forward in solving these challenges.

Kaushik Chatterjee (left) and Amit Nain (right)

Members of the Biomaterials and Tissue Engineering research group led by Kaushik Chatterjee at IISc

REFERENCE:

Nain A, Joshi A, Debnath S, Choudhury S, Thomas J, Satjia J, Huang C, Chatterjee K, A 4D printed nanoengineered super bioactive hydrogel scaffold with programmable deformation for potential bifurcated vascular channel construction, Journal of Materials Chemistry B (2024).

https://pubs.rsc.org/en/content/articlelanding/2024/tb/d4tb00498a

LAB WEBSITE:

https://sites.google.com/site/iiscbiomaterials/home