Adulteration of milk is a pressing concern in developing countries like India, where a majority of supplied milk fails to comply with the standards set by the Food Safety and Standards Authority of India. Water is frequently added to increase the volume of milk, along with urea, which makes the watered-down version whiter and foamier – this can potentially endanger the normal functioning of the liver, heart, and kidneys.

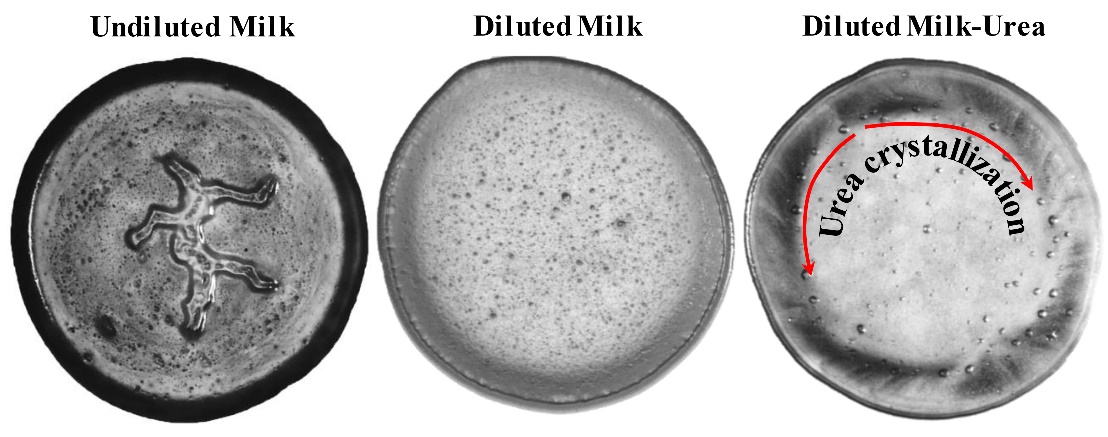

In this technique, the researchers looked at evaporative deposition patterns – those that emerge when a liquid mixture like milk completely evaporates, causing volatile components to dissipate, and solids or non-volatile components to arrange themselves in distinctive patterns. Milk with and without water or urea showed very different evaporative patterns. In unadulterated milk, the evaporative pattern consisted of a central, irregular blob-like pattern. Water was found to cause distortion or complete loss of this distinctive pattern, depending on how much is added. Urea also completely erases the central pattern; being a non-volatile component, it does not evaporate but instead crystallises, starting at the interior of the milk drop and extending along the periphery.

Current techniques such as using a lactometer and looking for changes in the freezing point of milk can be used to detect the presence of water, but they have certain limitations. For instance, the freezing point technique can detect water only up to 3.5% of the total milk concentration. In addition, although biosensors with high sensitivity are available to test for urea, they are expensive, and their accuracy tends to decrease with time. The IISc team, on the other hand, was able to detect water concentrations as high as 30% and urea concentrations in diluted milk as low as 0.4% using this type of pattern analysis. Therefore, the technique could be a convenient replacement when access to such equipment is not available. “It can be done in any place,” emphasises Kumar. “It does not require a laboratory or other specialised processes, and can be easily adapted for use even in remote areas and rural places.”

Kumar and Dash believe that this technique can potentially be extended to test for adulterants in other beverages and products too. “The pattern that you get is highly sensitive to what is added to it,” explains Dash. “So, I think this method can be used to detect impurities in volatile liquids. It will be interesting to take this method forward for products such as honey, which is often adulterated.”

Additionally, the simplicity of this method lends itself to easy automation, once the patterns for all adulterants and their combinations are standardised. These could be fed into an image analysis software, for example, which would compare a photo – even one taken with a mobile phone – of the sample’s evaporative pattern with other standard patterns to accurately detect the adulterants present.

“The next step that we are looking at is to test for a lot of other adulterants, such as oil and detergents that form an emulsion resembling milk,” says Dash. She and her team plan to continue work in this direction, creating a repository of patterns corresponding to various concentrations of different adulterants.

Kumar V, Dash S, Evaporation-based low-cost method for the detection of adulterant in milk, ACS Omega, 2021, 6, 41, 27200–27207.

https://pubs.acs.org/doi/abs/10.1021/acsomega.1c03887

CONTACT:

Susmita Dash

Assistant Professor

Department of Mechanical Engineering

Indian Institute of Science (IISc)

susmitadash@iisc.ac.in

080-2293 2962

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.