11 June 2024

– Sandeep Menon

The adsorbent stage (left) and remediation stage (right) in the pilot system in the lab (Photo courtesy: S3 lab, CST, IISc)

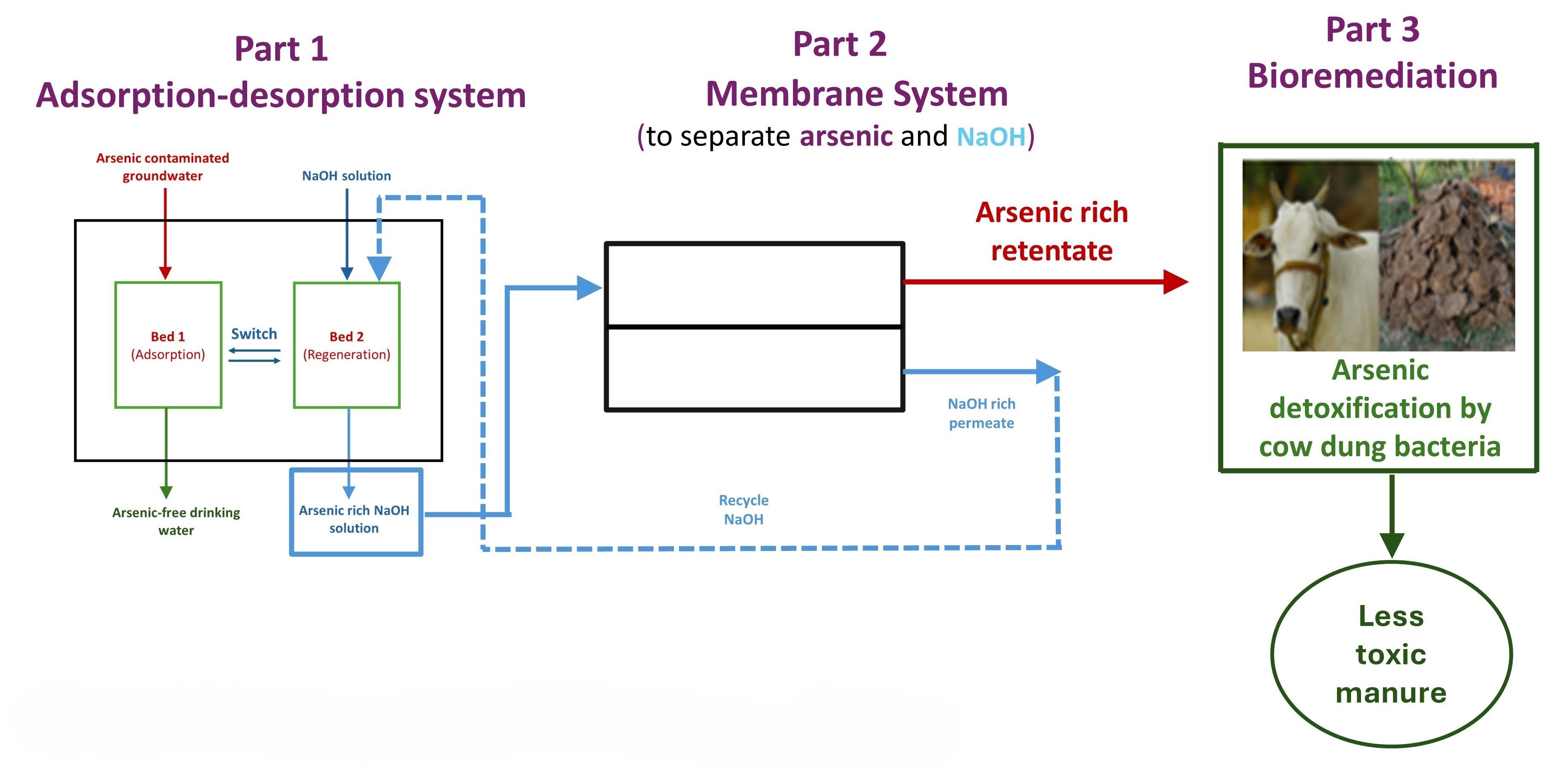

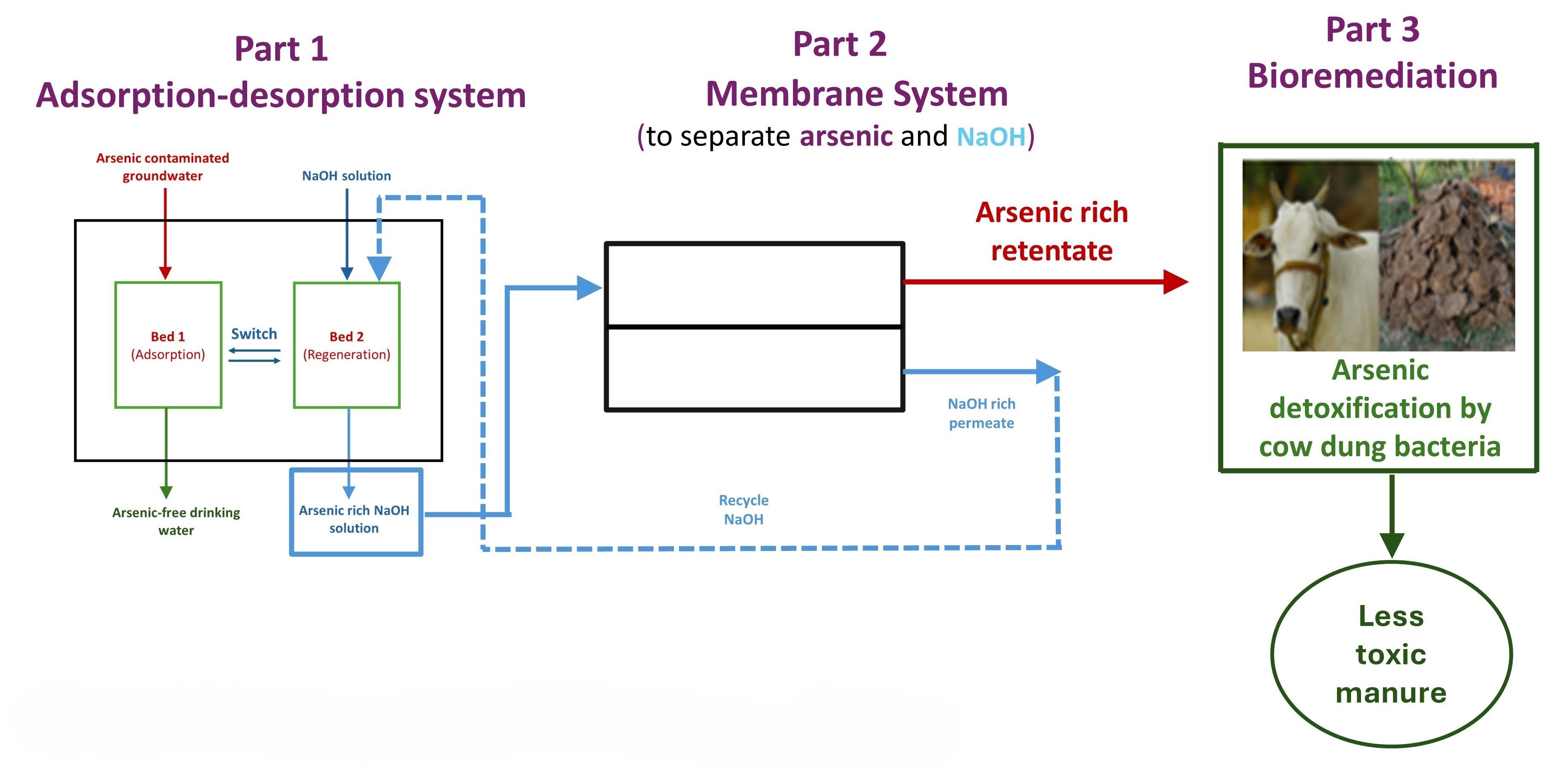

Researchers at the Centre for Sustainable Technologies (CST), Indian Institute of Science (IISc) have developed a novel remediation process for removing heavy metal contaminants such as arsenic from groundwater. The three-step method, which is patent-pending, also ensures that the removed heavy metals are disposed of in an environment-friendly and sustainable manner, instead of sending untreated heavy metal-rich sludge to landfills from where they can potentially re-enter groundwater.

“In every technology that exists, you can take out arsenic and provide clean water. However, after you remove the arsenic, you must do something about it so that it doesn’t re-enter the environment, and that aspect is not given due consideration in existing methods. Our process was designed to solve this problem,” says Yagnaseni Roy, Assistant Professor at CST, whose lab has developed the method.

According to reports, 113 districts in 21 states in India have arsenic levels above 0.01 mg per litre while 223 districts in 23 states have fluoride levels above 1.5 mg per litre, which are beyond the permissible limits set by the Bureau of Indian Standards and the World Health Organisation (WHO). These contaminants can significantly affect human and animal health, necessitating their efficient removal and safe disposal.

The first step in the process developed by the IISc team involves passing the contaminated water through a bed of biodegradable adsorbent made of chitosan – a fibrous substance obtained from crustaceans – doped with bimetallic (Fe and Al) hydroxide/oxyhydroxide. The adsorbent bed grabs the toxic inorganic arsenic through electrostatic forces and complex formation between arsenic and the adsorbent. A novel aspect of the technology is that the alkaline wash – used to repeatedly regenerate the adsorbent bed after its saturation – is recycled within the scheme.

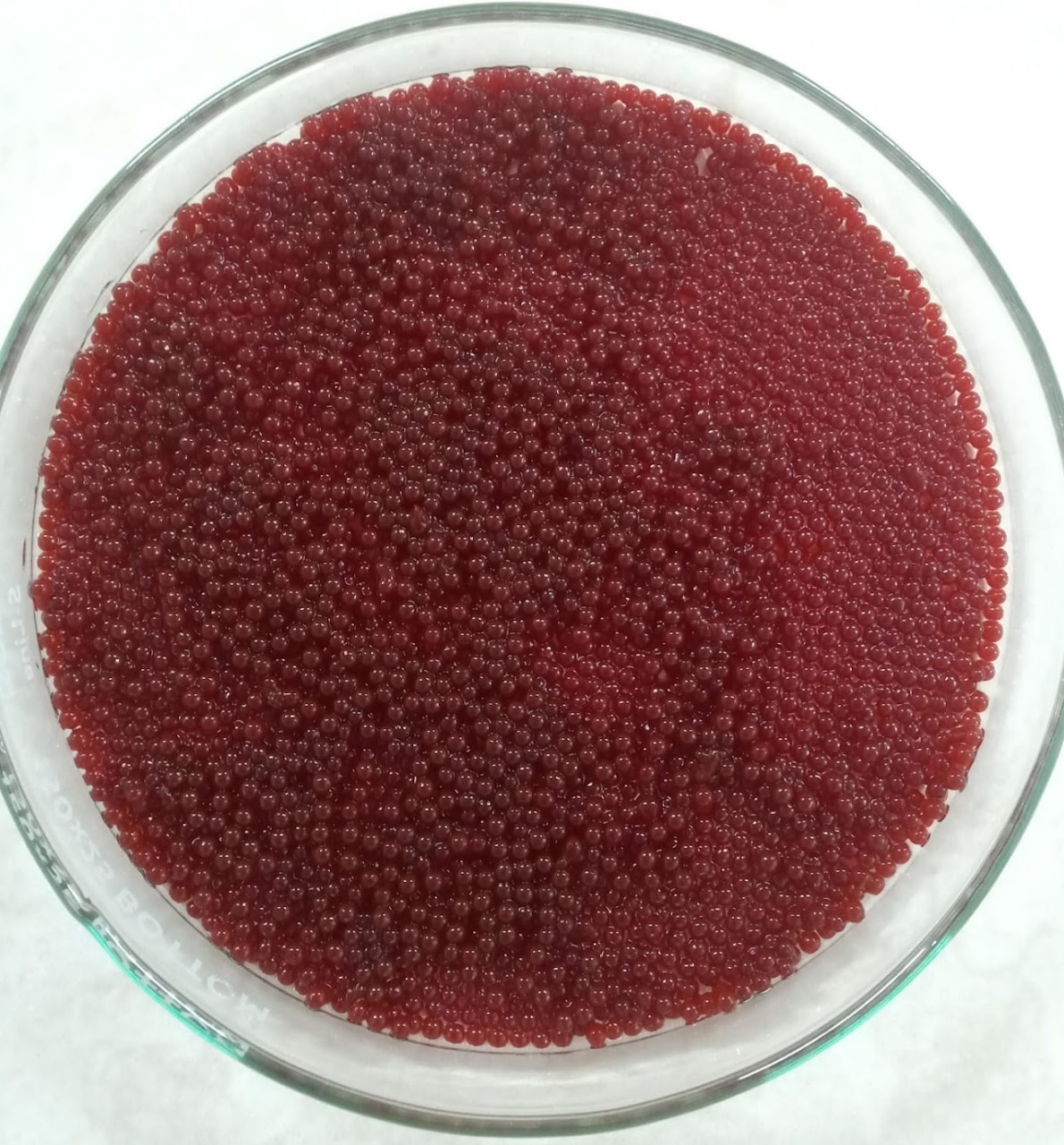

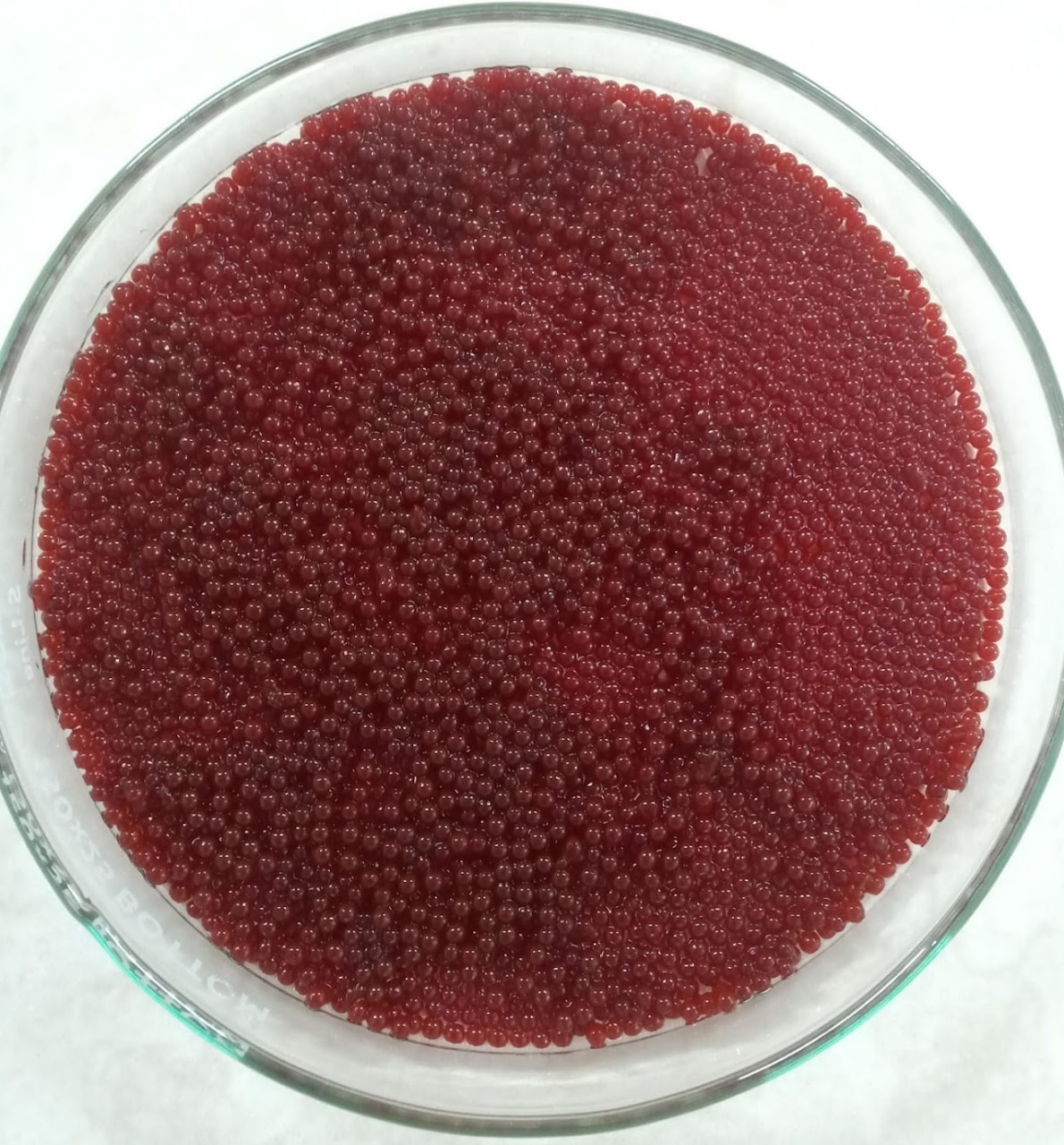

Close-up view of the adsorbent beads (Photo courtesy: S3 lab, CST, IISc)

In the second step, the alkaline wash solution, which is essentially sodium hydroxide and arsenic in water, is taken to a membrane system to separate the two. While the sodium hydroxide solution (the alkaline wash) is taken back to regenerate the bed, the arsenic concentrated in the other stream is now ready to be taken to the third step: bioremediation. The membrane process serves to concentrate the arsenic ahead of bioremediation.

In the bioremediation step, the toxic inorganic arsenic is converted to low-toxicity organic arsenic via methylation by microbes found in cow dung. This results in a decrease of toxic inorganic arsenic to below the maximum permissible limit specified by WHO standards, within a span of eight days. The remaining cow dung sludge can be safely disposed of in landfills, since the arsenic is locked in it in an organic form.

“On average, these organic species are approximately 50 times less toxic than the inorganic form present in groundwater,” says Roy.

The system can also be adapted to remove fluoride, with the last step changed to precipitation to form calcium fluoride, which has very low solubility in water. Roy’s team is currently checking the feasibility of tackling other heavy metals using the same system.

Schematic of the process (Image courtesy: S3 lab, CST, IISc)

The system is easy to assemble and operate. Manufacturing the adsorbent material involves a simple recipe. In the lab, a small pilot-scale adsorption column system was able to generate safe drinking water (by WHO standards) for two people for three days. The researchers have been working with INREM Foundation and Earthwatch, both NGOs, to deploy and test these systems in rural areas such as Bhagalpur in Bihar and Chikkaballapur in Karnataka.

According to the researchers, such a system would work best at the community level.

“The collection of waste, maintenance and operation are easier on a community scale than individual houses. The maintenance is simple enough that it can be operated by people in the community itself, which will help with income generation for people operating the system,” says Rasmi Mohan T, PhD student at CST who has worked on the process. “For a larger scale, we might need funding to take it to various parts of the country.”

Along with Roy and Mohan, Master’s student Subhash Kumar and post-doctoral fellow Manamohan Tripathy have also been involved in developing the scheme at both lab and pilot scales.

CONTACT:

Yagnaseni Roy

Assistant Professor

Centre for Sustainable Technologies (CST)

Indian Institute of Science (IISc)

Email: yroy@iisc.ac.in

Phone: 080 2293 3016

Website: https://www.s3iisc.com/home

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.