Additive manufacturing (AM), also known as metal 3D printing, creates objects by addition of material, layer by layer. A major source material for AM is metal powder, which is predominantly produced using a technique called atomisation, in which a molten metal stream is broken up into fine droplets using air or water jets. However, despite its widespread use, atomisation returns poor yield, is expensive, and is inflexible in the types of materials it can handle. A team of researchers at the Indian Institute of Science (IISc) led by Koushik Viswanathan, Assistant Professor at the Department of Mechanical Engineering, has identified an alternative technique to produce metal powders that side-steps these problems. This has interesting implications for AM processes in general, including areas such as the manufacture of biomedical implants.

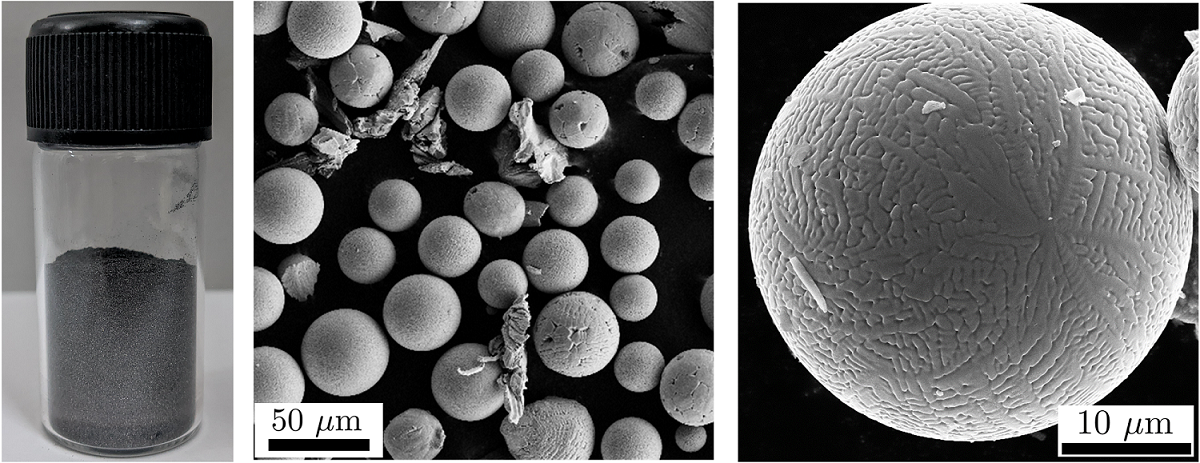

In the metal grinding industry, the material removed – called swarf – is often discarded as a waste product. It is commonly stringy in shape, like metal chips, but it often also throws up perfectly spherical particles. Scientists have long theorised that these bodies go through a melting process to take up the spherical shape, thus posing some interesting questions – does the heat from the grinding cause the melting? Is there melting at all? Viswanathan’s team showed that these powdery metal bodies form as a result of melting due to high heat from oxidation, an exothermic reaction, at the surface layer. They then refined this process to produce large quantities of spherical powders, which are collected and processed further to be used as stock material in AM. Their study shows that these particles perform just as well as commercial gas atomised powders in the context of metal AM.

Priti Ranjan Panda, a PhD student at IISc’s Centre for Product Design and Manufacturing and one of the authors of the study, adds, “We have an alternative, more economical and inherently scalable route for making metal powders, and the quality of the final powders appear to be very competitive when compared with conventional gas atomised powders.”

About the applications of their findings, Viswanathan explains, “There has been significant recent interest in adopting metal AM because by nature, it enables significant customisation and allows design freedom. However, the large cost of stock metal powders has been the stumbling block. We hope that our work will open new doors to making cheaper and more accessible metal powders.”

“Reducing the cost of the AM process (via economical powders) can widen the range of materials in situations such as manufacturing of biomedical implants, which could become cheaper and more accessible,” adds Harish Singh Dhami, a PhD student at the Department of Mechanical Engineering and co-author of this study. The researchers say that making metal powder using abrasion also has potential in other high-performance applications such as in aircraft engines, where a high degree of specificity and sophistication are required.

Currently, metal powders are typically produced at an atomisation facility, requiring transport for casting and recycling, thus setting up a big supply chain. This works for abundant metals like aluminium, Viswanathan points out, but for strategic materials (such as tantalum and lithium), where extraction alone is a complex process, it would be favourable to have a scalable process for producing metal powders. Then, in principle, the entire supply chain can be housed within a single facility – a possibility that their technique could offer.

REFERENCE:

Harish Singh Dhami, Priti Ranjan Panda, Koushik Viswanathan, Production of powders for metal additive manufacturing applications using surface grinding, Manufacturing Letters, Volume 32, 2022, ISSN 2213-8463

https://doi.org/10.1016/j.mfglet.2022.02.004

CONTACT INFORMATION:

Koushik Viswanathan

Assistant Professor

Department of Mechanical Engineering (ME)

Indian Institute of Science (IISc)

koushik@iisc.ac.in

+91-80-22932670

Harish Singh Dhami

PhD student, Department of Mechanical Engineering (ME)

Indian Institute of Science (IISc)

harishdhami@iisc.ac.in

+91-9447789656

Priti Ranjan Panda

PhD student, Centre for Product Design and Manufacturing (CPDM)

Indian Institute of Science (IISc)

pritipanda@iisc.ac.in

+91-9525076428

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.