22 October 2025

– Kedhar R Thyagarajan

A new study from the Department of Materials Engineering (MatE), Indian Institute of Science (IISc) describes a rapid method to recycle a commonly used plastic while preserving its desirable properties.

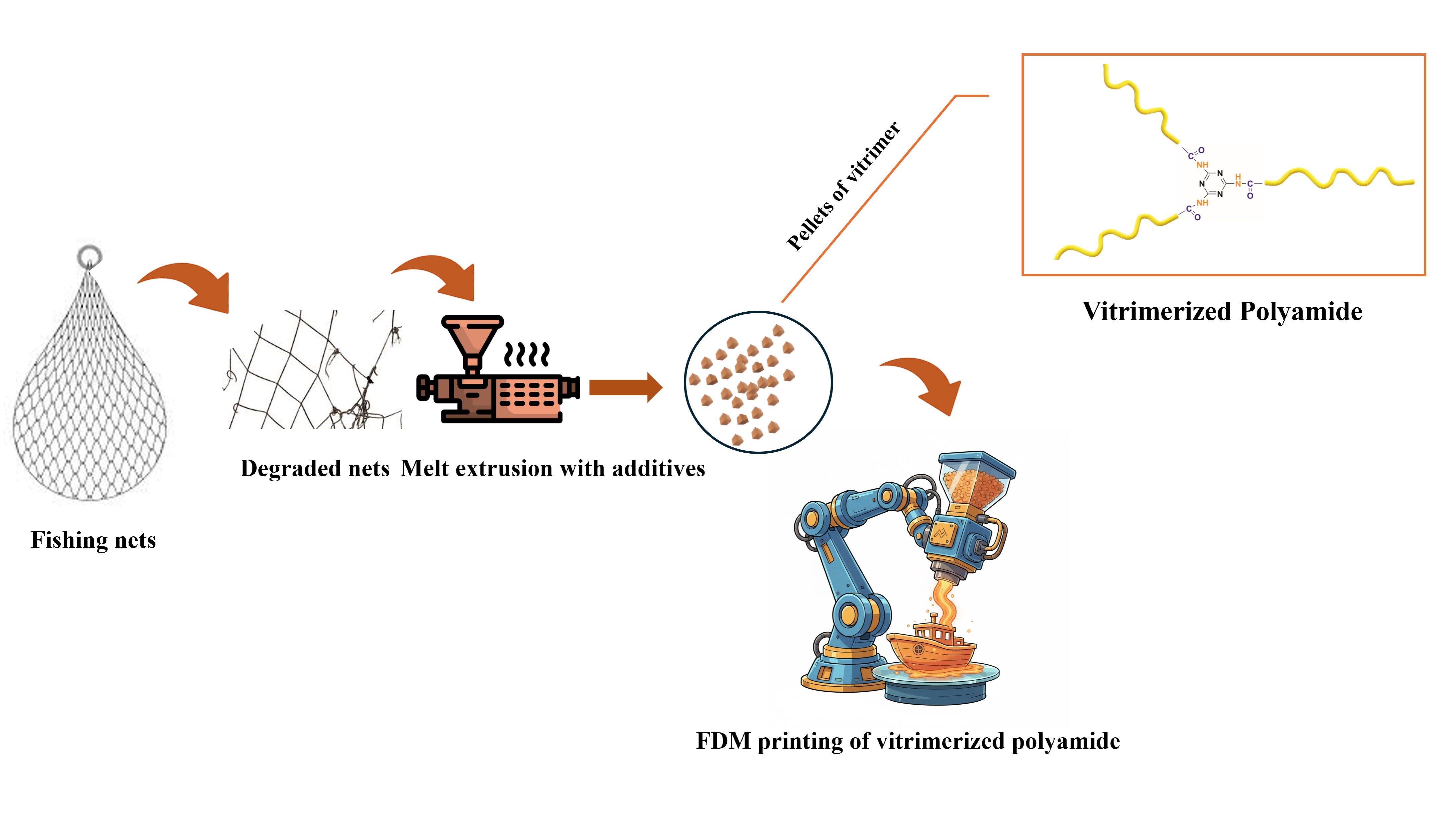

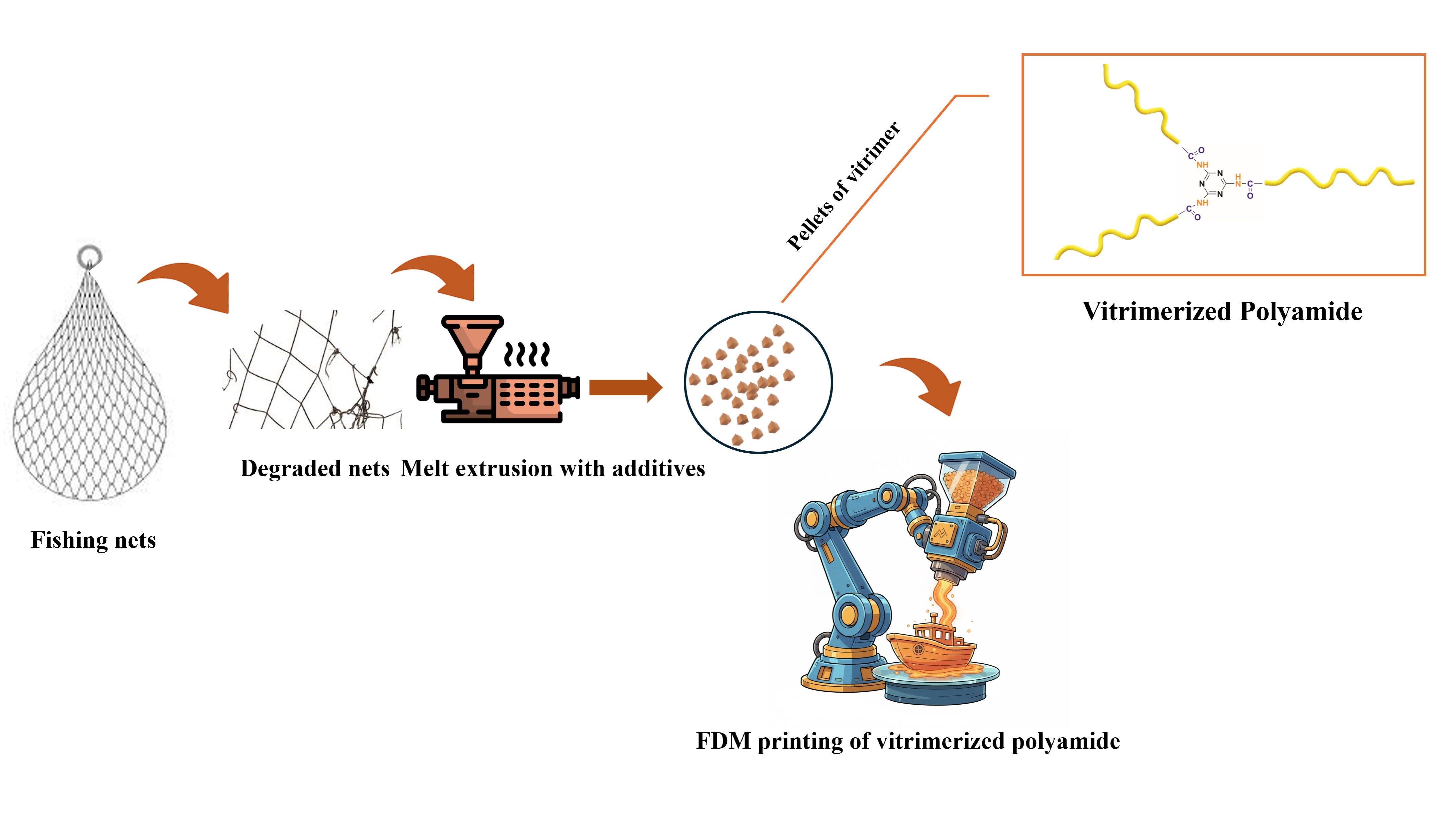

In the study, published in the Chemical Engineering Journal, researchers used a novel chemical process to recycle waste sourced from fishing nets and automotive parts. Such waste is often made of a type of polymer called PA-66 (Polyamide 66, commonly called Nylon 66) which is challenging to reprocess.

The process involves introducing a chemical cross-linker named melamine into the melted waste containing PA-66 in the presence of a catalyst. The resulting reaction, called transamidation, occurs fast enough to be carried out in high-throughput industrial extruders. “This method is designed for such industrial processes, which means that the reaction times are less than two minutes,” says S Vimal Kumar, PhD student in MatE and first author of the study. The end result is a nylon material that retains improved properties even after three reprocessing cycles.

From ocean to opportunity (Image: authors)

“Imagine taking a noodle strand. If you stir it too much, you are going to break it into smaller and smaller fragments,” explains Suryasarathi Bose, Professor in MatE and corresponding author of the study. “But if all those fragmented threads can be stitched together into a new molecule, you first deconstruct and then reconstruct the same noodle strand, but now with improved properties.”

The nylon generated from the recycling process was found to be quite strong and can be used for making products that require rigidity. “We are trying to see if it can be converted into park benches, road dividers or pavement tiles,” Bose explains. The short time taken to convert the waste into nylon also makes scaling up easier, the researchers say.

Bose is also the co-founder of a startup called VOiLA3D that uses such recycled materials to design products employed both in household items and civil infrastructure. The recycled PA-66 made using their process was tested to 3D print objects including a chair and a speedboat.

Humans produce over 430 million tonnes of plastic annually, according to the UN Environmental Programme. Material waste from fishing is one of the deadliest forms of such waste, threatening the lives of countless marine animals. Improved recycling processes for polymers like PA-66 can give the used plastic a new lease of life, while also incentivising waste collection.

REFERENCE:

Kumar SV, Deeraj BDS, Rege SS, Reddy AM, Prasanth SR, Islam SS, Dey I, Samanta K, Misra A, Bose S, From ocean to opportunity: Upcycling fishing net waste into high-performance, reprocessable nylons, Chemical Engineering Journal (2025).

https://www.sciencedirect.com/science/article/pii/S1385894725090370

CONTACT:

Suryasarathi Bose

Professor

Department of Materials Engineering (MatE)

Indian Institute of Science (IISc)

Email: sbose[at]iisc.ac.in

Phone: +91-80-22933407

Website: https://sites.google.com/site/polymerprocessinggroup/home

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.