Wearable electronic devices, worn on clothes or the skin to record body parameters such as heartbeat and pulse rate, are currently in great demand. 2D nanomaterials such as graphene, with their exceptional electrical and mechanical properties, play a key role in fabricating these devices. Graphene oxide (GO) is a scalable and low-cost alternative to pristine graphene. However, GO is an insulator and needs to be reduced to an electrically conducting form called reduced Graphene Oxide (rGO) to make it useful for sensors.

A group of IISc researchers has now devised a novel method to instantaneously reduce graphene oxide using an electric spark.

This method, outlined in a paper published in ACS Applied Materials and Interfaces, is efficient and cost-effective, which would allow easy industrial scale-up. It is also more environment-friendly compared to existing methods as it does not generate chemical residues. Sensors developed using this method can have applications in gesture control, in biomedical rehabilitation to detect the degree and intensity of body movements, and in the field of robotics.

Graphene and its derivatives are versatile in their electrical and structural properties, and are therefore the preferred materials used to build flexible sensors. The chemical structure of GO allows it to form ‘printable inks’ with various solvents, and bind to the substrate better. Various reduction techniques, including thermal, UV, laser, and microwave-based methods, are used to modify the chemical structure and form rGO. However, these methods are expensive and time-consuming, often produce toxic by-products, and can also damage the substrate.

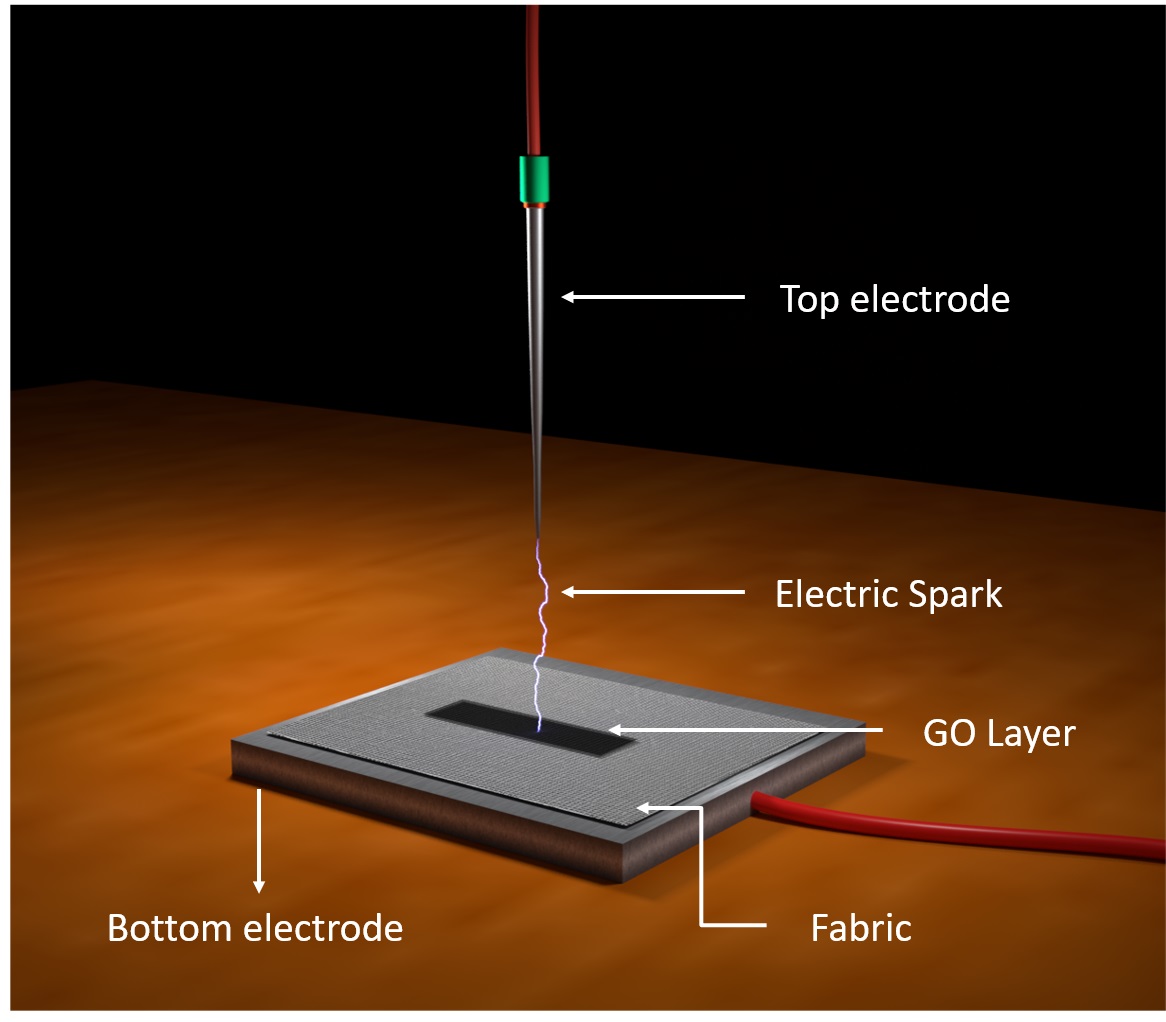

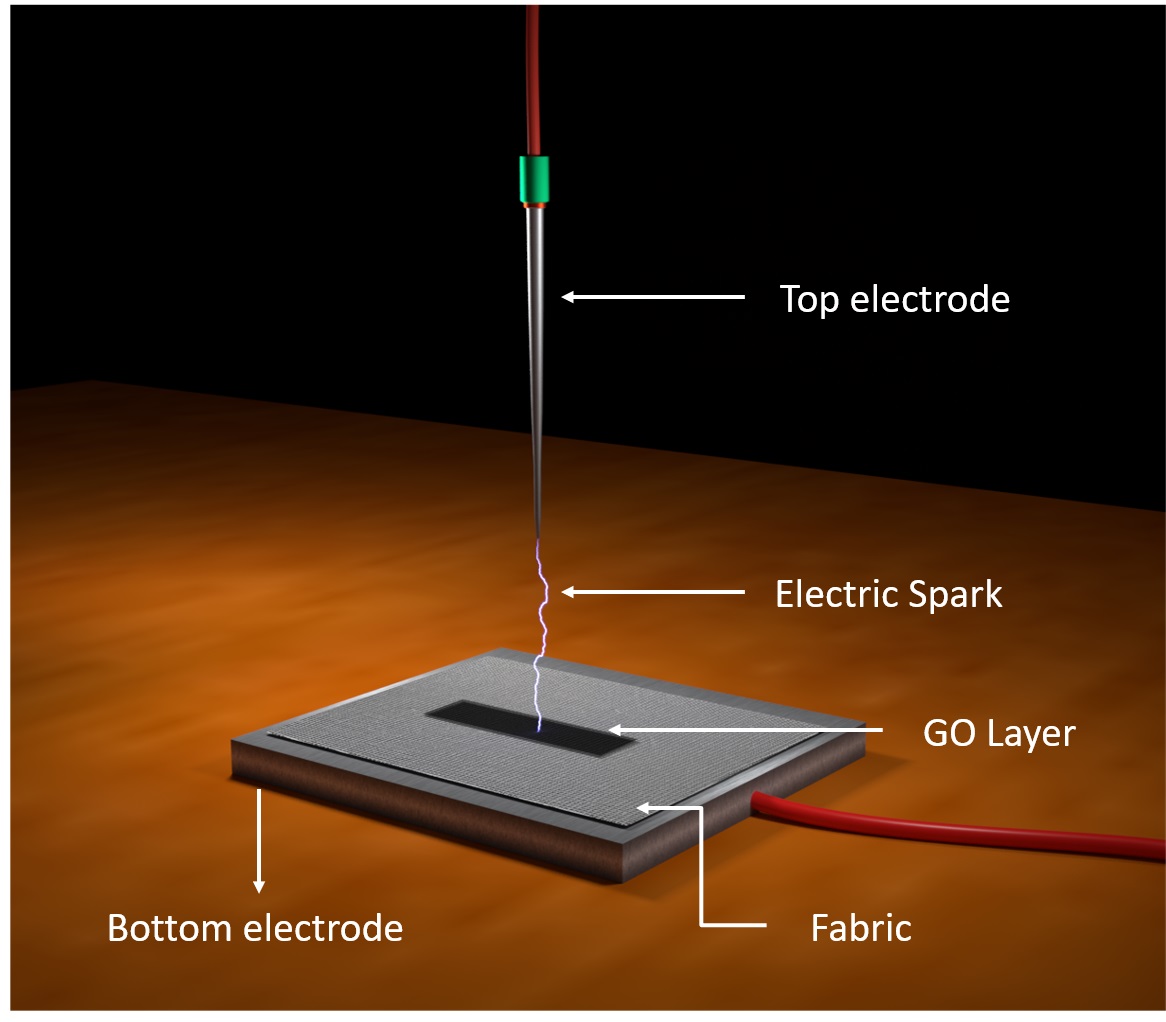

Schematic of the spark discharge setup with spark-dispensing electrodes and GO film deposited on fabric (Credit: authors/ACS Applied Materials and Interfaces)

To reduce graphene oxide efficiently and quickly, the IISc team used an electrical discharge under ambient conditions, popularly known as an electric spark. Sparking on GO deposited over a porous substrate enables its instantaneous reduction, along with a large drop in electrical resistance.

By varying certain parameters in the spark stream, the team was able to tweak the degree of reduction of graphene oxide, and also make predefined conducting patterns, which offers more flexibility in sensor fabrication. The heat present in the spark is highly localised and does not cause any substrate damage; this was verified using a Scanning Electron Microscope.

When mechanical stress is applied to the rGO-coated fabric, it causes a proportional change in the electrical resistance of the rGO film. This property is essential for it to function efficiently as a flex sensor. The change in electrical resistance was found to be consistent over repeated tests and under different bending angles, says Rajanna Konandur, Honorary Professor at the Department of Instrumentation and Applied Physics, and corresponding author of the paper.

He and his team integrated flex sensors containing these spark-reduced rGO films on commercially available gloves, and tested them using bending and other finger movements. Further research can pave the way for inexpensive, large-scale production of flexible, wearable electronics that use these films.

REFERENCE:

Kedambaimoole, V., Kumar, N., Shirhatti, V., Nuthalapati, S., Nayak, M. M., & Konandur, R., Electric Spark Induced Instantaneous and Selective Reduction of Graphene Oxide on Textile for Wearable Electronics, ACS Applied Materials & Interfaces, March 2020.

https://pubs.acs.org/doi/10.1021/acsami.9b22497

CONTACT:

K. Rajanna

Honorary Professor

Department of Instrumentation and Applied Physics

Indian Institute of Science (IISc), Bengaluru

kraj@iisc.ac.in

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.