State of the art biofunctional titanium alloys for joint replacement

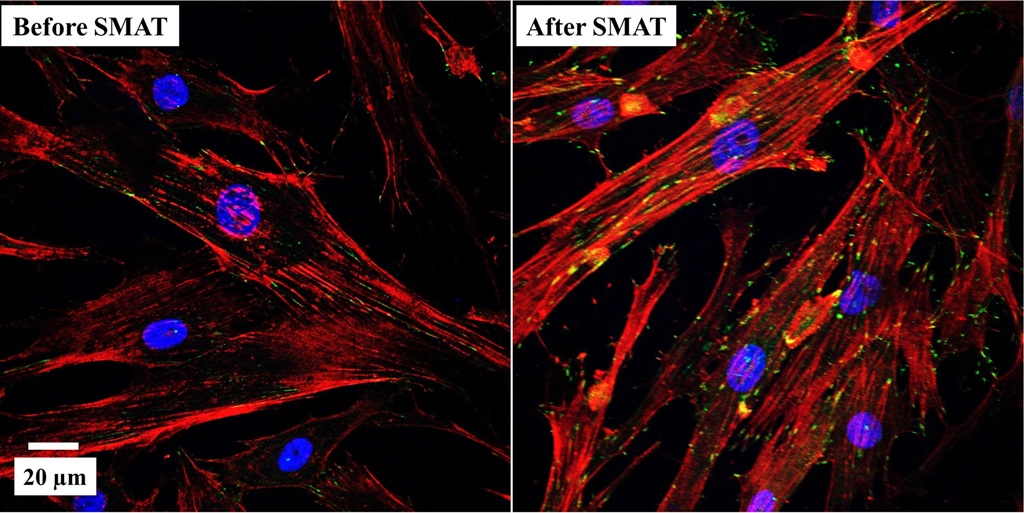

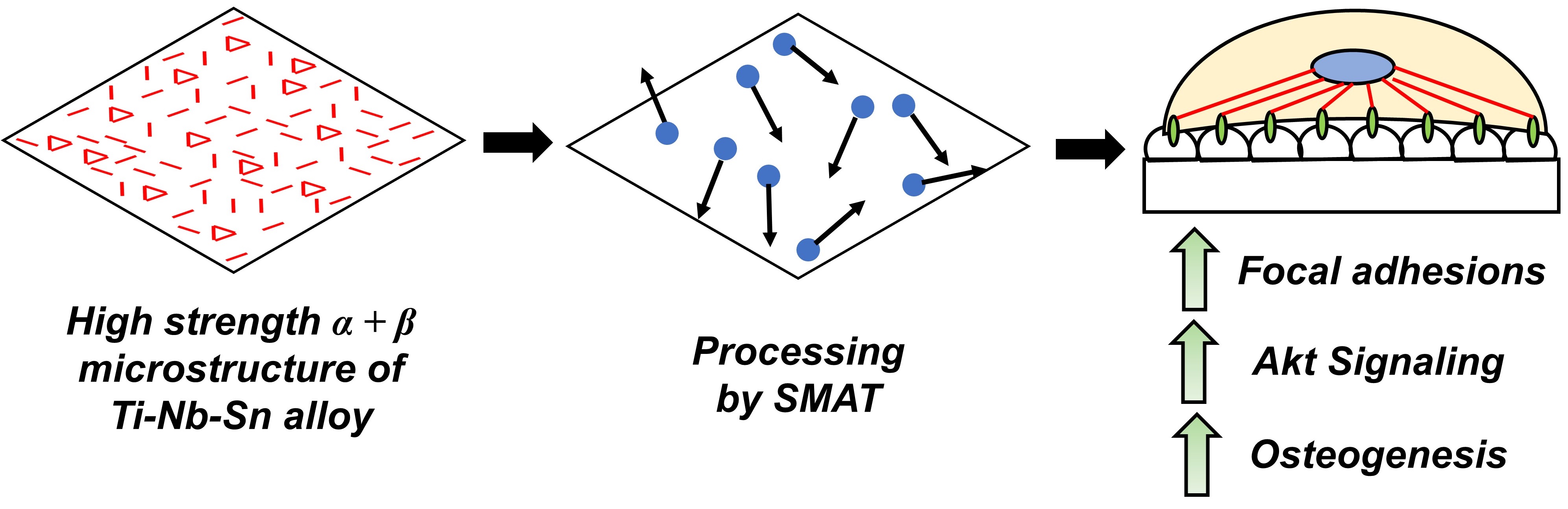

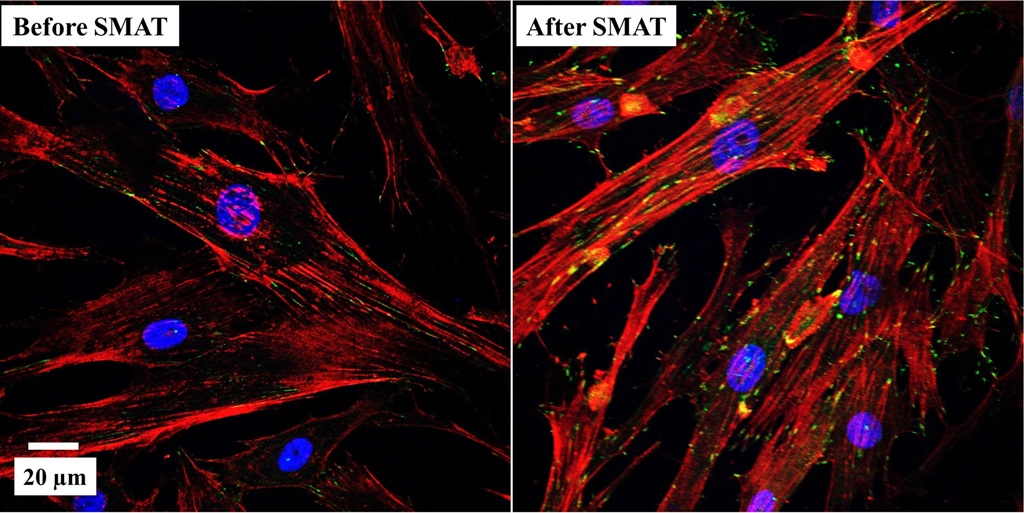

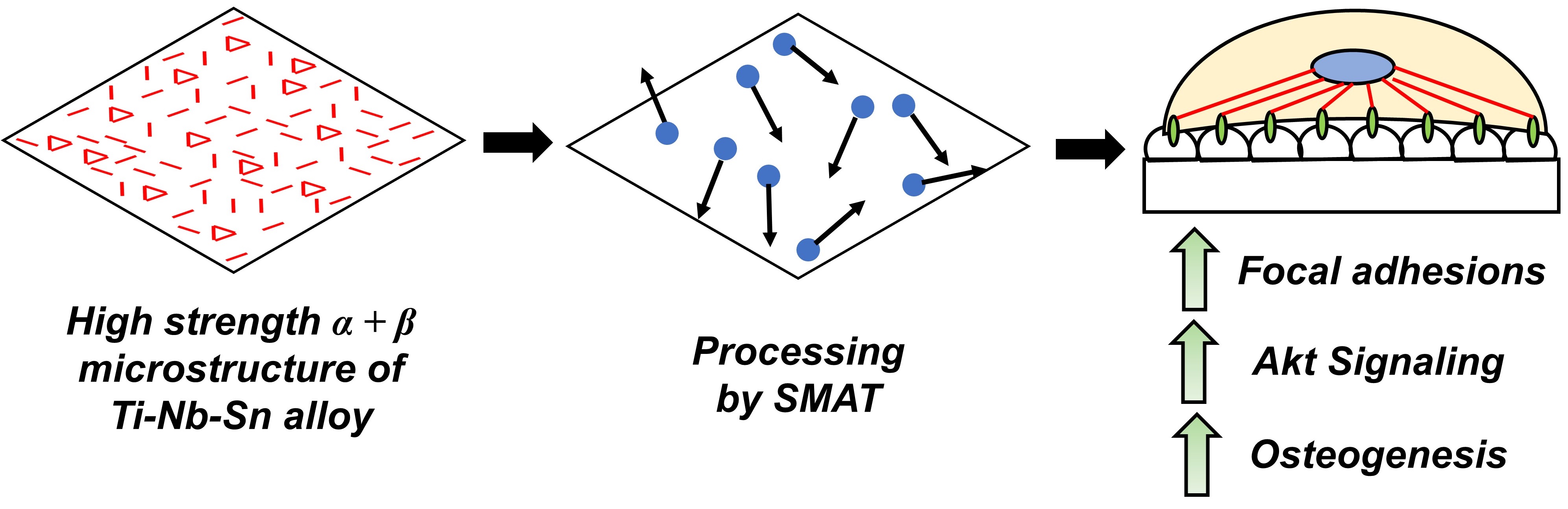

Metallic implants are used to replace dysfunctional bone joints (hip and knee) in patients suffering from osteoarthritis. The alloys used at present (316L, Ti-6Al-4V, Co-Cr-Mo), are stiffer compared to human bone and contain elements such as Al, V, Ni that have potential cytotoxic effects. Furthermore, they lack the necessary ability to bond with the surrounding bone (termed as osseointegration) or in other words are not bioactive. This has led to the development of new alloys that are less stiff, non-toxic and bioactive compared to existing alloys.In our work, we have developed a new high strength low modulus (less stiff) nontoxic β Ti-Nb-Sn alloy for joint applications. Subsequently,we have employed a facile yet innovative approach to improve the ability of the alloy to bond with the bone. In this approach, the surface of the alloy isseverely deformed byimpact of hardened steel balls moving randomly in space at high speed. Thisprocess that is used to deform the alloy surface is known as surface mechanical attrition treatment (SMAT). The impact of the balls increases the surface roughness at the nanoscale which in turn augmentsthe attachment of human mesenchymal stem cells by formation of more focal adhesions. This translates into higher production of bone mineral by stem cells (osteogenic differentiation). In other words, the potential ability of the alloy to bond with the bone increases after SMAT. This study indicates that SMAT is a promising strategy to engineer high performance orthopedic implants in the future[1, 2].

Figure 1: Confocal fluorescence micrographs of human mesenchymal stem cells showing formation of more focal adhesions after processing by SMAT that lead to enhancement in osteogenic differentiation

Figure 2 Schematic depictingthe enhancement of osteogenic differentiation of stem cells after processing the high strength β Ti-Nb-Sn alloy by SMAT

Group Website URL: https://sites.google.com/site/iiscbiomaterials/home; http://materials.iisc.ac.in/~satyamsuwas/;