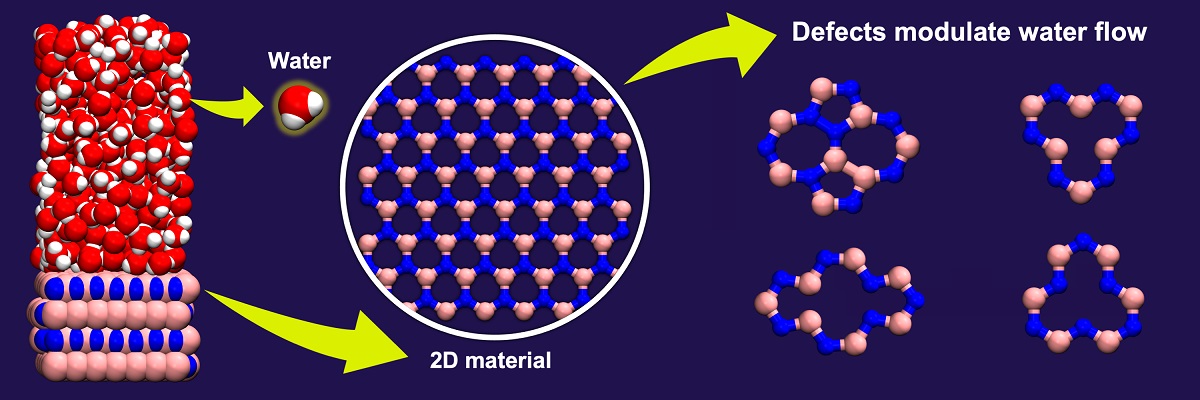

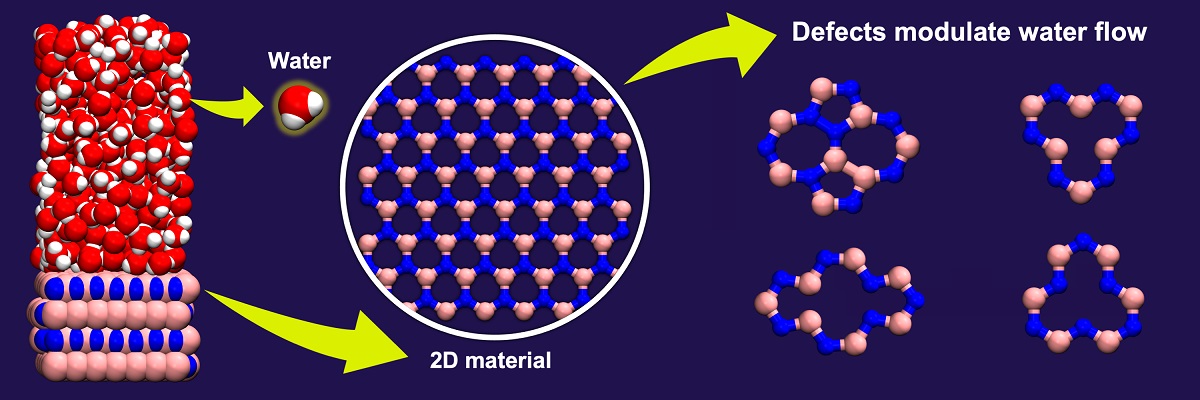

Defects in 2D materials predicted to modulate water flow

Two-dimensional (2D) materials, which consist of a few layers of atoms, are currently being explored for various applications, including seawater desalination, oil-water separation, and osmotic power harvesting. These materials often contain imperfections or defects in them, which can alter the properties of the material. Although defects in materials are usually thought to increase frictional forces, computer simulations show a notably different picture. These unexpected results were recently published in the journal Nano Letters by Ananth Govind Rajan, Assistant Professor in the Department of Chemical Engineering and Aniruddha Seal, an undergraduate student from the National Institute of Science Education and Research.

The team combined quantum-mechanical calculations of the charge distribution in hexagonal boron nitride (hBN), a 2D material, with classical molecular dynamics simulations of water interacting with hBN. Molecular dynamics simulations allow researchers to model the trajectories of atoms and molecules and to make predictions regarding frictional behaviour at the nanoscale.

Surprisingly, the authors found that certain defects, such as the nitrogen (N) vacancy (where a nitrogen atom is missing from the hBN lattice) and the Stone-Wales defect (where a boron-nitrogen bond is rotated by 90 degrees in the hBN lattice), led to a reduction in water-hBN friction. On the contrary, a boron (B) vacancy increased water-hBN friction almost threefold. The authors quantified these predictions in terms of the “slip length”, a quantity that determines to what extent water molecules “slip” on the hBN surface. They found that, at high defect concentrations, the slip length of hBN with a N vacancy could be comparable to that of graphene, the most slippery 2D material known to date. These findings have implications for the optimal and predictive design of devices made using hBN.

REFERENCE:

Seal, A.; Govind Rajan, A. Modulating Water Slip Using Atomic-Scale Defects: Friction on Realistic Hexagonal Boron Nitride Surfaces. Nano Lett. 2021, 21, 19, 8008–8016.

https://pubs.acs.org/doi/10.1021/acs.nanolett.1c02208

LAB WEBSITE: https://agrgroup.org